Process

Step 1

Cutting

Cut the round bar-shaped raw material to the specified specifications using a steel chopper or band saw.

Step 2

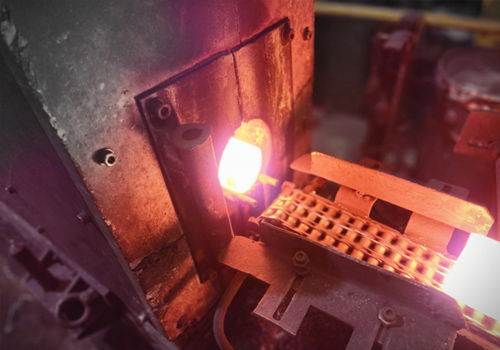

Material heating

The cut material is quickly and evenly heated to the optimal temperature suitable for forging processing through electric high-frequency heating.

Step 3

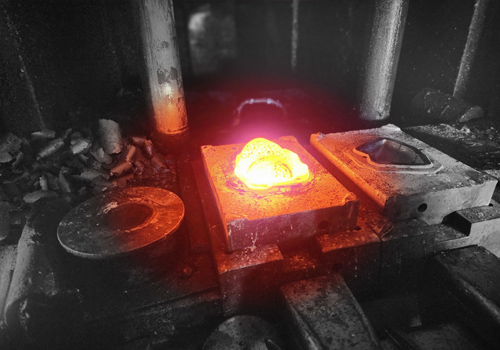

1st stage

The heated material is put into the press and goes through the 1st pre-forming process before creating the final shape.

Step 4

Secondary Forging

Apply strong pressure once again to the preformed material to complete the shape of the final product that matches the design drawing.

Step 5

Trimming

Burr, which is an unnecessary protrusion that flows out between the molds during the forging process, is neatly removed using dedicated press equipment.

Step 6

Post-processing

To improve the quality of the product, the surface is cleaned through shot processing, and durability and corrosion resistance are secured through acid treatment and heat treatment.

Step 7

Final Inspection

Measure the appearance and dimensions of the finished product, and attach an identification label only to products that have passed the inspection.

Step 8

Packaging

We carry out final packaging work according to specifications so that the finished product, which has completed all processes and inspections, can be safely delivered to the customer.